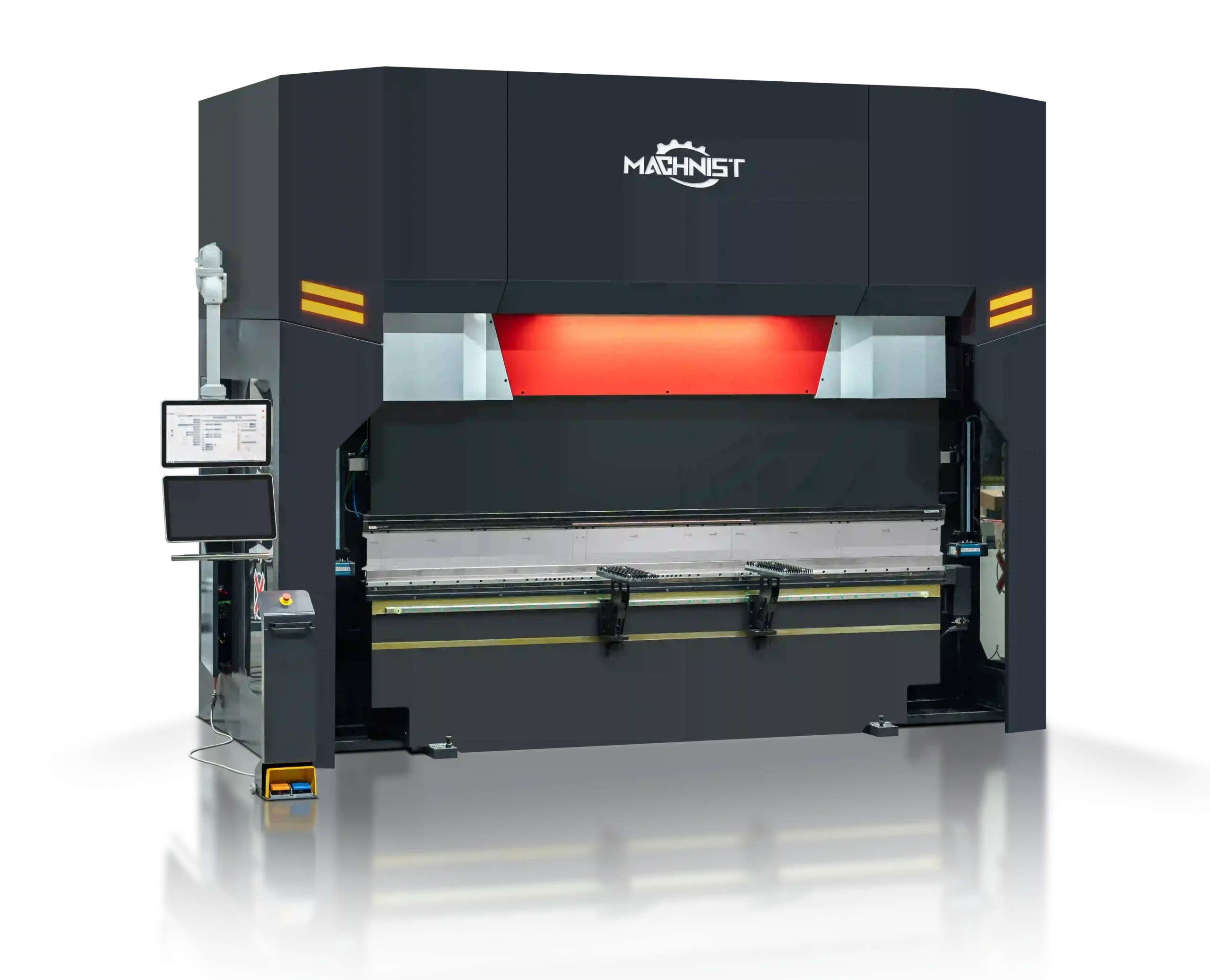

Press Brake

Manufacturer

Since 2008

Matching Your Needs With Factory Direct Prices

NC 110T/3200 from $10,666

CNC 130T/3200 from $14,800

*FOB for Google New Client Only

*Includes tonnage & spec analysis within 6 hours.

About Machnist®

Since 2008, Specialized in sheet metal bending . Helping company improve efficiency and precision.

*Including: Learn how to choose the right press brake based on performance and bending capability.

Torsion Bar Hydraulic —— NC

- Reliable and affordable, ideal for startups and workshops looking for a cost-effective bending solution.

Delivers consistent accuracy and stable performance, offering exceptional value across the 30–200 ton range.

- A mechanical torsion shaft synchronizes both cylinders, ensuring smooth, balanced, and precise bending motion.

| Tonnage | Length | Axes | Crowning | Controller |

|---|---|---|---|---|

| 30–200T | 1–6 m | X, Y | Auto (optional) | TP10S / E315 |

Proportional Valve —— ECO

Proportional valve control for precise flow, repeatability ±0.01 mm

Ideal for high-end sheet-metal fabrication and tight-tolerance production

| Controller | Backgauge | Safety | Clamp | Programming |

|---|---|---|---|---|

| DA53TX | X.R.Z1.Z2 | Half Cover | Euro Style | 2D |

Proportional Valve —— PRO

Powered by a main servo motor for energy efficiency and stability;

6-axis backgauge easily handles complex bending tasks;

WILA quick-clamp system for fast, precise tool changes;

Full enclosure with DSP laser safety system ensures top-level operator protection.

| Controller | Backgauge | Safety | Clamp/Toolings | Programming |

|---|---|---|---|---|

| DA66S/ESA860W | X1.X2.Z1.Z2.R1.R2 | Full Cover+ DSP | Wila | 2D/3D |

Servo Pump Hybrid —— MAX

Ideal for integration with robotic arms for long-hour continuous operation — stable oil temperature ensures consistent precision.

Extended cylinder stroke and increased open height make it suitable for a wide range of workpieces.

Faster return speed for higher productivity and overall efficiency.

| Controller | Backgauge | Safety | Clamp/Toolings | Programming |

|---|---|---|---|---|

| DA69S/ESA875W | X1.X2.Z1.Z2.R1.R2 | Full Cover+ DSP | Wila | 2D/3D |

Full Electric —— Ultra

Servo-driven precision ball screw ensures highly accurate and quiet operation;

No hydraulic oil, making it eco-friendly and maintenance-free;

Simplified structure for lower maintenance costs and higher reliability;

Ideal for precision metal parts fabrication and clean manufacturing environments.

| Tonnage | Transmission | Backgauge | Clamp/Toolings | Controller |

|---|---|---|---|---|

| 8-100T | Reducer | X.R.Z1.Z2 | Euro/Wila | Syntec/Esa 875 |

Hear from our clients

Our clients love working with us, just read what they have to say!

Need help finding a machine?

Contact Us

We will gladly assist you in making the right decision to achieve your business goals.

Responding to all pre- and after-sales questions within 2 hours.

- +86 199-555-30940

- Info@machnist.com

More About Machnist

Factory Acceptance Test

Every machine is tested and signed off before shipment.

- Leveling & pre-run – frame leveling, oil/pressure set

- Geometry check – ram parallelism, table straightness

- Axis calibration – Y1/Y2 sync, backgauge X/R/Z

- Accuracy & endurance – repeatability, 4–8 h run

- Safety & electrics –e-stop, light curtain, CE wiring

After-sale Support

Training

- Operator / Application / Maintenance

- SOP + parameter backup

- Certificate provided

Remote Support

- Reply ≤2h (business hours)

- WhatsApp / Email / Video (Teams/Zoom)

- Backgauge & Y1/Y2 calibration, alarms, safety reset

Factory Acceptance Test

Parts wear over time. For Machnist machines, we keep spare parts ready and guide you through fast replacement to minimize downtime.

- Restore like-new performance

- Fair, transparent pricing

- Reliable quality extends service life

Tip: Wear items are consumables—keep a starter kit in stock to avoid delays.

FAQ

Can Machnist customize press brake machines?

Yes. Machnist offers OEM customization for press brakes, including appearance, color, configuration, controller, safety options, and more to meet specific needs. Please note that customized products may carry a slightly higher price.

How does Machnist ensure the machine fits my needs?

Before ordering, Machnist’s sales and engineering team will communicate in detail to understand your requirements and recommend a configuration tailored to your application—prioritizing the best solution rather than the most expensive one.

Do Machnist press brakes comply with international safety standards?

Yes. All Machnist press brakes comply with international standards such as CE and ISO. The machines are equipped with multiple safety devices, including light curtains (photoelectric protection) and emergency stop circuits, to protect operators.

What control systems are available for Machnist press brakes?

Machnist offers renowned controller brands, including DELEM, CYBELEC, ESA, and ESTUN (commonly for NC press brakes). These controllers ensure precise and efficient operation.

How do you ensure product quality?

Before shipment, our QC team records every inspection process on video for customer verification — including the slider positioning accuracy, backgauge parallelism, and vertical alignment. Each machine is fully tested and approved before leaving the factory.

Do new customers get any discounts or bonuses?

Yes. For new customers coming through Google channels, we offer a free tooling cabinet with the first order as a welcome gift.

How can distributors cooperate with you?

We provide exclusive regional protection for distributors. Machnist supports local exhibitions and directs potential customers in that region to our authorized agents for follow-up and service.

What payment methods do you accept?

We accept T/T (bank transfer) and Letter of Credit (L/C).

Special orders are supported — please contact us for details.